|

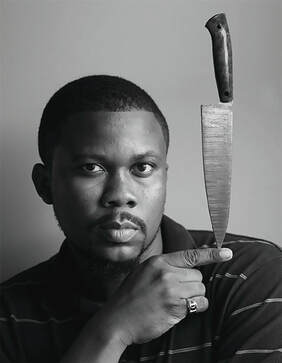

Middleton Made Knives. Image by Diana DeLucia.  Quentin Middleton, Founder, Middleton Made Knives. Quentin Middleton, Founder, Middleton Made Knives. I had a wonderful time interviewing this young and talented Bladesmith, Quintin Middleton of Middleton Knives deep from the heart of South Carolina where his passion for knives is turning up the heat. ~ Leo Bushey GK: Quintin, would you like share with us who you are and how you were inspired to make beautifully handcrafted precision blades for the definitive chefs? I am the maker and owner of Middleton Made Knives. My knife passion started as a young boy. I wanted to make swords. My fantasy sword was Conan the Barbarian’s sword, that’s where it all started. Anytime I would watch a fantasy film; my imagination would just run wild. I wanted to be Conan, Luke Skywalker, He-Man, or any Samurai or Knight in the movies. The medieval era is what I wanted to reenact. Fast forward a few more years; I began working in a local mall selling knives, cigars, and memorabilia swords. One day, Jason Knight came in to buy a sword, and he told me that he made knives for a living. I asked him, “Can you teach me how to make knives?” After this, he became my mentor. He primarily makes Bowie knives, fighter knives, and hunting knives. He was one of the judges on the TV show "Forged in Fire." GK: How did you get into making knives for culinarians? After several years of making hunting knives and swords I had a dream. God told me to make chef knives. From hearing that voice, I decided to make a list of every top chef in Charleston. I called every last one of them and asked them if they would be interested in purchasing my knives, every last one of them turned me down. Craig Deihl, the Executive Chef of Cypress, was the one that gave me an opportunity. He didn’t buy anything because truthfully my knives were based and shaped by hunting knives. They were thick and really heavy. He gave me his input on what a professional chef would want in the kitchen. After that advice, I made him a knife and tested it for a few weeks. He gave me more insights and advice, and from that information, I created what he desired. I’ve been making knives for 15 years now, and I’ve been making chef knives for seven. GK: Where has your market grown? Who are some of the chefs that use your knives? My knives have been sold all across the USA, from South Carolina, California, Hawaii, to Australia. I’ve been featured in Ebony magazine, Vogue Italy and mentioned in GQ magazine. Sean Brock and Emeril Lagasse are famed keepers of my custom pieces, and the list just goes on and on. GK: What is the process of forging a knife? After I discover whether my client wants a stainless steel knife, high carbon steel knife, or a Damascus knife I then forge the sheet, cut the excess material away, and grind the profile of the knife. Once I have the template, I fire it in a kiln. If it’s stainless steel, I will heat it to 1,920 °F, and if it’s high carbon, I will bring it to 1,500 °F. GK: Wow. That’s pretty hot. How long does it stay in the kiln? Do you hit it with a hammer? Yes. That’s when I’m forging. Heat treating, that’s another process. Forging is when you have a smaller piece of steel, and you’re trying to stretch it and pull it to the width and the size that you need. It’s similar to making pizza dough, for example, when I’m kneading the dough to form a ball, I stretch it out with a hammer by repetitive hard strikes to the correct width for the pizza I am making. That’s exactly what I am doing with steel except with blacksmith tools and at a very high temperature. GK: Do you buy American Steel? I have a supplier in New Jersey. Once I receive the steel, I’ll either forge it, or I will do a process called stock removal. From there, I would take it to heat treating, which is when the knife is heated to the critical temperature of 1,920 °F or 1,500 °F. After that, it begins changing the crystal structure inside the steel making it much harder, and it creates a stronger edge. After it's removed from the kiln, I dip it in oil, which shocks it and cools it quickly so that the knife will be hard, but very brittle, it’s almost like glass. If I were to take that knife and hit it against a table, it would probably snap in half at this stage of the process. The next step is called tempering. Tempering is a cooling method of taking the stress out of the steel. I’m baking it at a lower temperature, around 200 °F or 400 °F, for an hour or two to relieve the stress in the steel. Now I have a knife that is tough and has a high wear resistance. I can take that knife and put it in a vise, and bend it at a 90-degree angle without it breaking, making it very durable. GK: Have you passed all the quality specifications for your knives? Yes, certain groups in the knife world test your knives. I am a member of the ABS, American Bladesmith's Society and I’ve passed all cut and bend tests. GK: Tell us about your handles. I use a lot of wood, especially maple burl which is the knot or the growth that comes off the side of the tree, the big knot part. I have a friend who customizes the block method for me. He’ll either dye it or stabilize it. I then take each block of wood and hold it up to God to see which one speaks to me. Each knife has its own personality. Another type of wood I use is Dymalux or Dymondwood. It’s veneered birch that’s compressed together like plywood. It's kept under high pressure with resin and glue, so it's a really tough material. They use it making archery and gun stocks. GK: Absolutely. I’m looking at them right now. They’re just fascinating. Tell us about the swirls and spirals on the blade. Is that a certain technique you do to develop that? That is called Damascus steel. It’s a layering technique to create different patterns in the steel. You start off with two different types of steel, one that has chromium, another that has a higher carbon content, and you will mix those two together. That’s how you achieve the contrast between dark and light. The steel that has more chromium or nickel will stay light, and the steel that has the higher carbon content will turn dark. GK: Is this a Japanese method of how they make their knives? Correct. GK: They say that the Japanese method of forging steel is impeccable. Absolutely. GK: Can you talk about your oyster knife a little bit? When I came up with the idea for the oyster knife, (the brew shucker), it was Christmas time. My family was all around shucking oysters. They would use screwdrivers; some would have butter knives, they all had different gadgets to pop oysters. My uncles, who would be drinking beer, were opening their bottles on the picnic table to remove their caps. A vision came to me, and I thought, “why not create a knife that could shuck oysters and open beer bottles?.” GK: What kind of price range can chefs or knife enthusiasts expect? The top price ranges from $240-$440 for an eight-inch chef knife. We have a three-knife Echo set for around $500. The full price list can be found on my website at: www.middletonmadeknives.com GK: What can our readers expect from Middleton Made Knives in 2018? I’ll be creating my own signature style of pocketknives, and I also have some other ideas in the kiln! GK: Tell us about the pocket knives. One of the pocket knives I have called Ajaani which is a Nigerian name which means the man that survives the struggle. It’s an old-type of gentleman’s knife. I’ve seen a lot of tactical knives, and a lot of really tough, heavy knives. This one will be a dress-up knife that you can take to special occasions when you don’t want to have your heavy tactical knives in your jacket pocket or your pants! It will be light and will not weigh you down. ~ by Leo Bushey

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |